A unique chance to make the industry cleaner and safer by a multidisciplinary approach

Multidisciplinary view on the energy transition

Increasing sustainability of vessels urges for the increase of service life of mechanical parts to achieve higher returns. Siebe Sietzema, Managing Director of Sietzema Techniek, explains: “A few years ago we produced a new propulsion shaft liner for a maritime customer. The original liner was totally worn within one year. We rebuild the part and used a tungsten carbide coating to protect the spare part. This newbuild spare part is still in place and extended the service life with more than five years. As a result, losses due to machine downtime are kept to a minimum.”

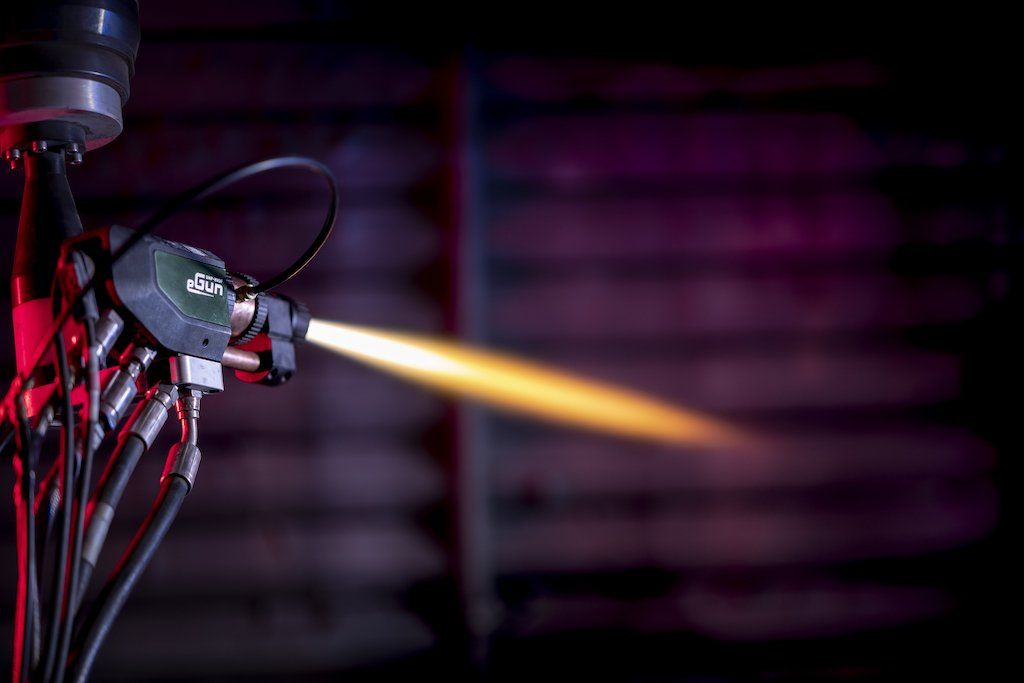

Beside propulsion shaft liners, the techniques used by Sietzema Techniek are suitable for pumps, compressors, plungers, and seals. “In thermal spraying we use eGun technique to spray denser coatings with higher wear resistance and better corrosion resistance — cost-effective and sustainable.”

Take sustainability one step further

Rinke Wesseling, Sales Manager at Global Electrical Solutions, explains: “To assist our maritime customers to achieve compliance with the EEXI Legislation, we are investigating available and suitable decarbonization technologies and operation changes for vessels, ultimately providing the best solution in terms of reduction of EEXI & CII and return on investment (ROI).”

One solution is adapted for managing highly variable load peaks, without polluting emissions. “Peak shaving allows energy production to be scaled according to the ship's nominal operating needs. For example, extra power is needed when entering and leaving ports and when berthing and unberthing. With peak shaving you avoid peaks in energy consumption that are inefficient, unnecessary, and costly. Fluctuating energy demand is strenuous for energy assets like generators and grid connections. Our batteries clip these peaks, resulting in significant savings. Peak shaving on the grid can save up to 30% on costs compared to the use of traditional diesel generators.”

Reducing costs and downtime by monitoring

Automation and monitoring contributes to better insight, safety, and higher returns. Allan Nijholt: “Recently we implemented a dashboard to control and monitor the electrotechnical status of the installations. This can also be done for the key mechanical parts. Insight reduces downtime and makes investments very specific. You can be sure you invest there where investments and replacements are needed.”

A unique chance to make maritime safer

Although the strategy set for the maritime industry is challenging, it offers a unique chance to make the industry cleaner, more sustainable, and safer. Increasing the uptime of crucial spare parts, peak shavings, and monitoring the electrical and mechanical performance are a few examples of investments that already proved to bring more than high returns. It can be steps towards a cleaner and safer industry

About Global Electrical Solutions

With over 20 years of experience in the maritime and heavy industry Global Electrical Solutions is your partner for hybrid systems, for electrification, engineering, inspections, and installation of smart electrical solutions. Whatever the challenges, our experts design, engineer and build new installations from scratch or refit your installations on-site.

Global Electrical Solutions

Rinke Wesseling

rinkewesseling@globalelectricalsolutions.nl

www.globalelectricalsolutions.nl

About Sietzema Techniek

The determination, flexibility and craftsmanship of the employees result in high-quality products and solutions. As a team, we are constantly looking for the best solution for each specific wear and tear problem. We are a small team of specialists with the utmost determination to deliver top quality for our customers. Because the spare and wear parts we supply make a world of difference to our customers.

Sietzema Techniek BV

Siebe Sietzema

siebe@sietzematechniek.nl

www.sietzematechniek.nl